Even if you primarily sell online, your packaging is the first direct touch that your brand has with your customer. It’s an important part of a memorable experience and an incredible branding tool.

Custom compostable packaging ensures that your product will create a unique experience that builds a connection with your customer.

Whether you're a seasoned brand owner or launching your very first product line, we’re here to help you find a compostable packaging solution that aligns with both your business goals and sustainable brand values.

What is Minimum Order Quantity (MOQ)?

A Minimum Order Quantity (MOQ) is the lowest number of units that a supplier or manufacturer will produce at one time. When you order custom packaging, the MOQ is the smallest number of packaging units that you would need to purchase per order.

MOQs are not unique to packaging, many products we buy regularly also have MOQs! If you think about recent trips to the grocery store you will likely have purchased something only available as a pack of 6, 12, 24, etc. Baked goods such as cookies, muffins, and bread rolls are made in batches and usually also sold in batches. The MOQ for blueberry muffins at your grocery store might be 6.

MOQs are important to consider when you plan inventory and budget. They will directly impact the cost per unit, lead time, and overall investment in your compostable packaging solution.

Why do Minimum Order Quantities Exist?

Manufacturers need to ensure that a production run is as efficient as possible. When setting minimum order quantities a manufacturer will consider the cost of production, cost and availability of raw materials, labor, shipping, and storage.

Thinking again about baked goods, it would be incredibly inefficient (not to mention difficult) for a baker to make one single blueberry muffin. However, they might agree to sell you a single blueberry muffin if they know that other customers will buy the remaining 11.

Our stock cellophane bags and pouches are sold in packs of 100, and our blank labels in packs of 25 sheets. Because stock packaging is not printed with a unique brand design, we are able to make the MOQ for stock products lower and therefore more accessible to small businesses.

Custom Packaging Printing and Production

Production and printing methods also play a role in setting MOQs. All of our custom compostable packaging products are inline printed. Before being converted into pouches, the compostable material is stored in large rolls. Inline printing means that the rolls of material are printed before being made into pouches, bags, or labels.

Inline printing is higher quality, faster, and more efficient than post-production printing (printing on packaging after it has been made). The more complex setup needed for inline printing does mean that the minimum order quantity is set higher. However the speed and efficiency means that packaging can be produced at a lower cost per unit, which can provide significant savings in the long run.

Sustainable Custom Packaging

Slower or less efficient methods of packaging production allow for lower minimums, but they take more time and use more energy. To ensure that your compostable packaging is sustainably produced, we use high-efficiency production methods that require less energy and create less waste.

We track our production waste closely! We are able to reduce production waste by simplifying and optimizing our designs to ensure the most efficient use of raw materials. But production waste is not only offcuts and edges of material, it also includes material processed as the machine is starting, stopping, or undergoing testing.

Each production run incurs a fixed amount of “setup waste”. Before production begins, material is run through to ensure that the machine has been set up correctly. Setup waste is part of the process of setting up the machine, it can’t be avoided entirely but it can be reduced.

Because setup waste is a fixed amount, the amount of waste will be the same whether you’re producing 1000 or 100,000 pouches in a single production run. This means that longer production runs create less waste and are more sustainable overall.

While we do send unusable production waste to our compost partners for composting, we also set MOQs that allow us to minimize the amount of waste that occurs in the first place.

Read More About Designing for Sustainable Packaging Production

Elevate Packaging MOQs

We carefully set our MOQs to help you get the highest quality, most sustainable packaging at the best price per unit.

| Custom Packaging Solution | MOQ | |

| Compostable Pouches | 5000 | Get Quote |

| Compostable Labels | 2000 | Get Quote |

| Compostable Cello Bags | 10,000 | Get Quote |

How to Get the Most Out of Your Custom Packaging Order

High MOQs can seem like a big barrier for small businesses and start-ups, but here are a few tips to get the most out of your custom compostable packaging!

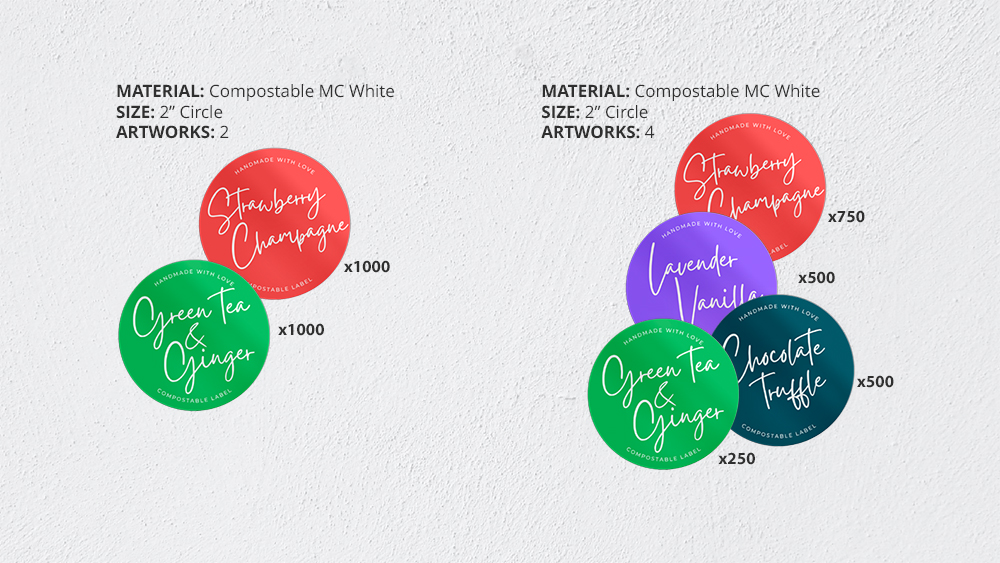

Mix and Match Artwork

Personalization is powerful. Custom printed packaging and labels offer a great opportunity to fine-tune every aspect of your design and artwork. If you have multiple SKUs —perhaps different colors, flavors, or scents—you may want to differentiate the packaging so that customers can easily see which flavors are available.

With a little optimization you can print multiple artwork designs and have them all count towards the MOQ!

How does it work?

- Ensure that your packaging or labels are all made of the same material

- Design your packaging or labels so that they are all the same dimensions

- Print as many different designs as you need!

Incorporate Seasonal or Promotional Designs

Perhaps your product will be available in different seasonal scents or flavors at different times of the year. Maybe you’re printing product labels but also need promotional labels. Could you incorporate them into the same order?

Using our Mix and Match Artwork rules (made of the same material, and using the same dimensions) you can print your seasonal or promotional packaging at the same time as your regular packaging and have them all count towards your MOQ!

Consider a Combination of Custom and Stock Packaging

Not ready for custom pouches? If your small business doesn’t quite meet the minimum order quantity for a fully unique custom compostable packaging solution, consider pairing stock pouches or cellophane bags with custom labels. Custom compostable labels have a lower MOQ than our custom bags and pouches. Many of our small businesses customers find that pairing custom labels with our compostable stock pouches can provide a unique branding experience with a more accessible MOQ and lower upfront investment.

Ready to start your sustainable packaging journey?

Connect with one of our packaging experts

Contact Us